Tank Farms

Internal and External Coatings

Risk weighted, quantify/qualify inspections/review of the conditions of existing coatings systems, and project future degradation to efficiently manage maintenance painting programs. +20 years audit system in use for to identify “appears sound”, “practical repairs”, “full replacement” and “metal loss” conditions of coated carbon and stainless steel, and degradation of galvanized. Prioritization for spot severe corrosion – chemical micro-environments, steam leaks, product spills, and cooling tower drift zones. Secondary containment and tank lining systems management are also available.

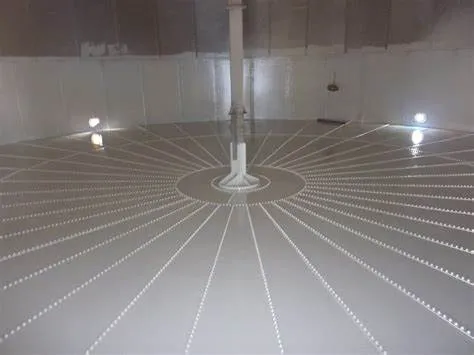

Tank Lining